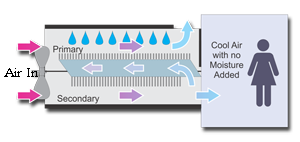

The recent advent of "Dew Point" cooling provides a new and highly economical commercial evaporative cooling technology.

Taking design cues from the acient Roman hypocaust, the Integrated Evaporative technique demonstrates a genuine potential for widespread applicability.

![]()

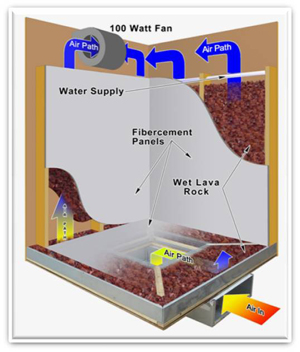

In the summer of 2005 a subscale prototype of the Integrated Evaporative system was constructed and demonstrated in Panama City, Florida.

Prototype features:

Lava rock filled floor and walls

A living space area of 80 cubic feet and 28 cubic feet of lava rock

Air was transported through the walls and floor via a 100w centrifugal blower

Drip rails supplied water at the top of lava bed within the walls

The interior walls were tightly joined so no air could short-circuit the designed path

No attempt was made to control interior humidity

An air inlet was fashioned in the base of the prototype floor. The floor and walls were filled with absorbent, lava rock gravel. A centrifugal exhaust fan above the ceiling provided air flow through the floor and walls. A drip rail above each wall served as a water supply. A temperature data logger was suspended in the living space center.

![]()

The graph at right indicates ambient and prototype interior temperatures, as well as ambient relative humidity. Noted at top are the midday peak temperature differentials.

The chart at right is a listing of temperatures that can be delivered by "swamp coolers".

Indicated in bright green is the performance (83°F) of the prototype at mid-day on July 24, 2005 with an ambient temp of 102°F and RH of 49%. Indicated in dark green is the typical performance (90°F) of a swamp cooler at given ambient conditions.

![]()

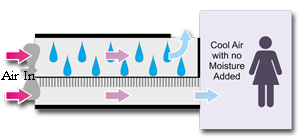

Placing the evaporator within the perimeter walls and floor yields IE's greatest advantages over centralized systems: "Dynamic Insulation" and "Thermal Flywheel" effect

Outdoor heat and indoor heat are both absorbed by evaporating water within the gravel bed.

Heat that migrates to the evaporator is vented outside the building.

Decentralized evaporator yeilds a 100% effective thermal barrier within the floor and walls when the system is running.

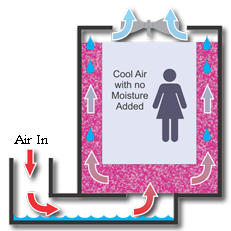

High mass and high specific heat capacity of liquid water, concrete, and rock gravel yield a very large thermal mass.

High thermal mass provides a pronounced "thermal flywheel effect".

Thermal flywheel continues to provide human comfort when the system is idle.

Integrated Evaporative

Provides temperatures within the human comfort range in humid climates